What is the level of oil in the crankcase sight glass? You should be able to see the oil level in the sight glass. The system controls have not been properly set.Lack of proper “winter-charge” of refrigerant.The system has not been properly adjusted and balanced.The system refrigerant piping is not designed or sized properly.

Here is a general listing of possible causes of oil failure trips, followed by a description of each: Often, however, the cause is not noticed and is more difficult to figure out, calling for detective work to keep the refrigeration system operating. Sometimes, the actual cause of the trip is obvious for example when there is no oil showing in the crankcase sight glass. If it has tripped, the fun begins, when the mechanic must figure out what caused the oil failure control to open. When the service person gets a call that the refrigeration system is not operating, one thing checked is whether the oil safety control has tripped. On both controls, the opening of the safety contacts breaks the electrical current in the system control circuit. This control also requires a manual reset once it has tripped. This signal causes the control module to open the safety contact points after a time delay. In the electronic control, the pressure sensor sends a signal to the control module whenever the pressure sensed falls below 7-9 psig. The control requires a manual reset once it has tripped. The control used most often on Copeland™ compressors is set to open the safety contact points after a short time delay whenever the net oil pressure falls below nine psig. In the mechanical control, the total pressure from the pump, less the suction pressure is the actual net oil pressure. The electronic control has a special pressure-sensor that mounts in the outlet of the pump and connects only with an electrical cable. The two basic controls we are most familiar with are the ‘mechanical differential control’, and the ‘pressure sensing electronic control.’ The mechanical control uses tubing that senses the suction pressure of the compressor and the outlet oil pressure of the pump. There are several types of oil safety control devices on the market today.

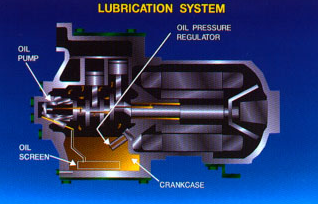

It is the action of the oil safety control we will discuss in this text. Most compressors that have positive oil pumps also have a control that senses oil pressure and acts as a safety device whenever the oil pressure falls below a certain threshold level. Many refrigeration compressors serviced today have positive displacement oil pumps to help lubricate the internal compressor parts.

0 kommentar(er)

0 kommentar(er)